Filament Winding Machine

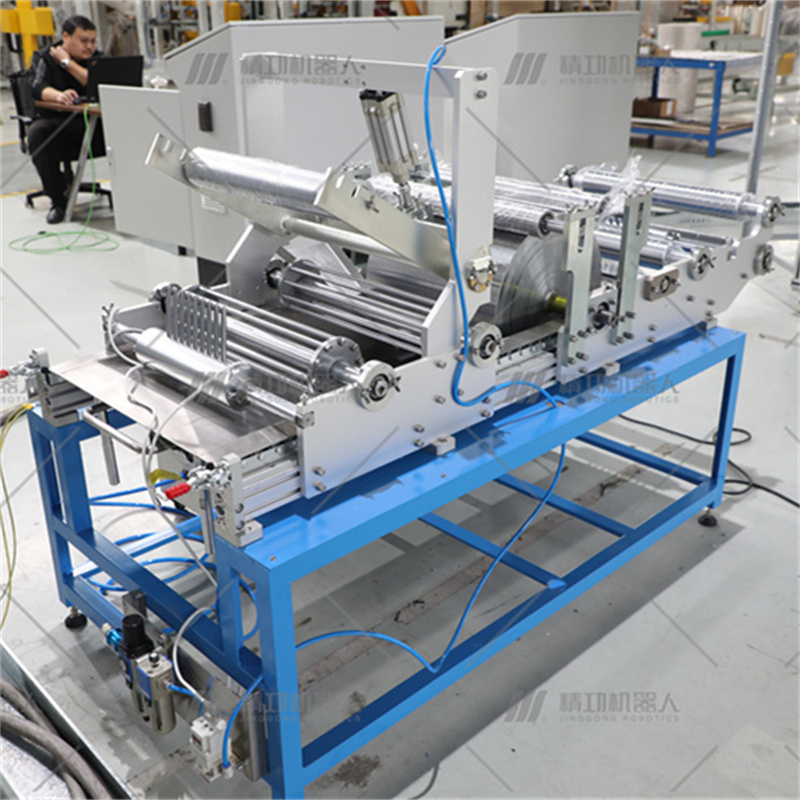

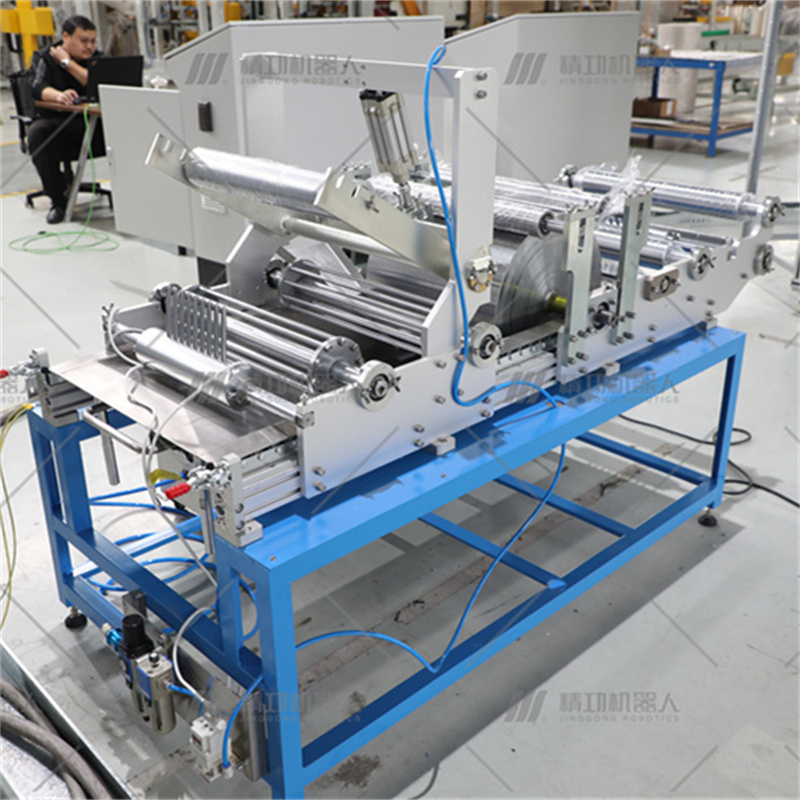

Description

1.The frame of the bobbin unwinding rack is connected by aluminum profiles.

2.Per rack has 8/12 unwinding spindles, and each spindle has one active unwinding electric motor.

3.Spindle Load: Max. Weight 12kg; Max. OD 270mm, tension control included.

4.Holes for filament are made of ceramic(easily worn-out part).

5.Equipped with a sliding door with improved door and rail materials to improve durability and firmness.

Tech Specs:

|

1 |

The filament winder adopts a welded frame with an anti-corrosive treatment to the surface. |

|

|

2 |

Pneumatic chuck fixture realizes automatic loading and unloading | |

|

3 |

Winding Diameter |

Max. Φ600mm |

|

4 |

Winding Length |

Max. 2500mm |

|

5 |

Spindle Speed |

0~100r/min |

|

6 |

Holes for filament are made of ceramic(easily worn-out part). |

|

|

7 |

Multi-Axis numerical control system with AC servo motor control. |

|

|

8 |

Automatic filament cutting and applying are optional. |

|

|

1 |

The filament winder adopts a welded frame with an anti-corrosive treatment to the surface. |

|

|

2 |

Pneumatic chuck fixture realizes automatic loading and unloading | |

|

3 |

Winding Diameter |

Max. Φ600mm |

|

4 |

Winding Length |

Max. 2500mm |

|

5 |

Spindle Speed |

0~100r/min |

|

6 |

Holes for filament are made of ceramic(easily worn-out part). |

|

|

7 |

Multi-Axis numerical control system with AC servo motor control. |

|

|

8 |

Automatic filament cutting and applying are optional. |

|