Carbon Fiber Precursor Production Line

Description

The carbon fiber precursor production method that adopts Dimethyl Sulfoxide(DMSO) as the solvent, Acrylonitrile(AN) as the first monomer, Itaconic Acid as the second monomer, AIBN as the initiator to have a binary copolymerization, and the dry-jet wet spinning is the top choice agreed among carbon fiber experts.

Tech Specs:

|

No. |

Item |

Unit |

Specifications |

Remarks |

|

1 |

Linear Density |

dtex |

1.15 |

|

|

2 |

Tensile strength |

CN/dtex |

≥4.0 |

|

|

3 |

Elongation |

% |

12±2 |

|

|

4 |

Dimethyl Sulfoxide(DMSO) Content |

% |

<0.03 |

|

|

5 |

Oil Content |

% |

0.5-0.1 |

|

|

6 |

End Breakage Rate |

% |

<3 |

|

|

7 |

Moisture Regain |

% |

≤1 |

|

|

8 |

Appearance |

No Apparent Broken Filament |

Process:

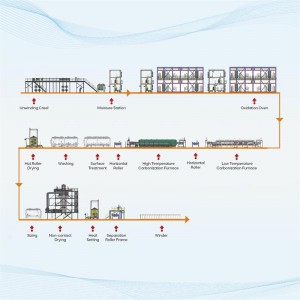

Raw Material Preparation —→ Monomer Mixture —→ Copolymerization —→ Primary Filtration —→ Monomer Removal —→ Secondary Filtration —→ Mixed Batch Neutralization —→ Tertiary Filtration —→ Storage —→ Defoam —→ Spinning —→ spin bath (Primary) —→ spin bath (Secondary) —→ spin bath (Tertiary) —→ Clean —→ Hot Stretching —→ Oiling —→ Drying —→ Steam Stretching —→ Heat Setting —→ Antistatic Treatment —→ Precursor Winding

|

No. |

Item |

Unit |

Specifications |

Remarks |

|

1 |

Linear Density |

dtex |

1.15 |

|

|

2 |

Tensile strength |

CN/dtex |

≥4.0 |

|

|

3 |

Elongation |

% |

12±2 |

|

|

4 |

Dimethyl Sulfoxide(DMSO) Content |

% |

<0.03 |

|

|

5 |

Oil Content |

% |

0.5-0.1 |

|

|

6 |

End Breakage Rate |

% |

<3 |

|

|

7 |

Moisture Regain |

% |

≤1 |

|

|

8 |

Appearance |

No Apparent Broken Filament |

Raw Material Preparation —→ Monomer Mixture —→ Copolymerization —→ Primary Filtration —→ Monomer Removal —→ Secondary Filtration —→ Mixed Batch Neutralization —→ Tertiary Filtration —→ Storage —→ Defoam —→ Spinning —→ spin bath (Primary) —→ spin bath (Secondary) —→ spin bath (Tertiary) —→ Clean —→ Hot Stretching —→ Oiling —→ Drying —→ Steam Stretching —→ Heat Setting —→ Antistatic Treatment —→ Precursor Winding