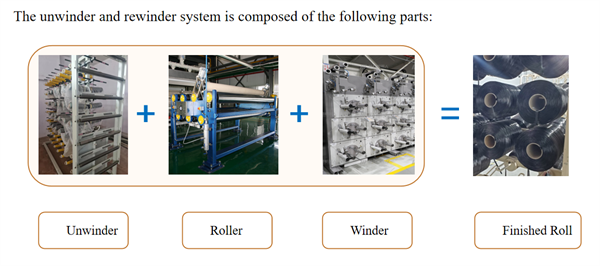

Unwinder and Rewinder

Description

--Unwinder:

It is used for large-sized carbon fiber filament roll placing and unwinding. The unwinder is embodied by mechanical expansion shafts, follower, guide rollers, and guide rolls.

—Roller:

It is used to lead out of unwinded carbon fiber filament at a uniform velocity. The roller is composed of linkage rollers, guide rollers, and guide rolls.

—Winder:

The winder realizes automatic length counting, filament cutting, and roll changing. Each set of winders has 9 heads, a control unit, and a printer.

Tech Specs

1.This system is used to unwind the large-sized carbon fiber filament roll, and rewind the filament into a small-sized roll.

2.Large-Sized carbon fiber filament roll(unwind): Max. weight: 8.5kg, Max. Diameter: about 220mm.

3.Small-Sized carbon fiber filament roll(rewind): Weight: 1kg, 1.6kg, 2kg, or others. The weight of the carbon fiber filament roll rewinded can be set through the operator interface by the user.

4.Paper tube size for rewinding: ID 76.5mm × OD 82.5mm × L 280mm.

5.The mechanical width of carbon fiber roll winded is 250mm, the actual width winded varies with the K range. Theoretical width= 250mm + carbon fiber filament width.

6.Filament Range Rewinded: 6 K, 12 K, 24 K, or 48 K (400 Tex, 800 Tex, 1650 Tex, 3300 Tex).

Advantages:

1. The carbon fiber winder developed by JG Robotics realizes the winding of carbon fiber filament ranging from 1k, 3k to 48k, and 50k.

2. The carbon fiber winder realizes automatic length counting, roll changing, filament cutting, winded roll pushing out, label printing, and so forth.

3. The carbon fiber winder is integrated with ports for automatic roll unloading, robot signal connection, and communication. It is capable of the expansion of function with automation.

4. The carbon fiber winder realizes speed following, and emergency stop, the winding speed of each head adapts with the whole system. No winding failure occurs in the emergency stop.

5. The winding process resumes after the emergency stop is lifted.

6. The winder adopts the ergonomic design, and the operation position and roller height are fine-tuned for manual filament leading.

7. Each winder is well-sealed with positive inside pressure, which avoids carbon fiber filament going inside, a stable winding process can be guaranteed.

FAQ:

Videos of setting up and debugging can be offered?

winder installation and production, winder operation, remarks of debugging, daily maintenance, monthly maintenance, yearly maintenance, and so forth.

In warranty period: Due to equipment failure caused by the equipment itself, the seller should offer free repairment and related service; due to equipment failure caused by the buyer, the seller charges only the cost of spare parts.

Out warranty period: The seller offers online technical support and service.

1.This system is used to unwind the large-sized carbon fiber filament roll, and rewind the filament into a small-sized roll.

2.Large-Sized carbon fiber filament roll(unwind): Max. weight: 8.5kg, Max. Diameter: about 220mm.

3.Small-Sized carbon fiber filament roll(rewind): Weight: 1kg, 1.6kg, 2kg, or others. The weight of the carbon fiber filament roll rewinded can be set through the operator interface by the user.

4.Paper tube size for rewinding: ID 76.5mm × OD 82.5mm × L 280mm.

5.The mechanical width of carbon fiber roll winded is 250mm, the actual width winded varies with the K range. Theoretical width= 250mm + carbon fiber filament width.

6.Filament Range Rewinded: 6 K, 12 K, 24 K, or 48 K (400 Tex, 800 Tex, 1650 Tex, 3300 Tex).

1. The carbon fiber winder developed by JG Robotics realizes the winding of carbon fiber filament ranging from 1k, 3k to 48k, and 50k.

2. The carbon fiber winder realizes automatic length counting, roll changing, filament cutting, winded roll pushing out, label printing, and so forth.

3. The carbon fiber winder is integrated with ports for automatic roll unloading, robot signal connection, and communication. It is capable of the expansion of function with automation.

4. The carbon fiber winder realizes speed following, and emergency stop, the winding speed of each head adapts with the whole system. No winding failure occurs in the emergency stop.

5. The winding process resumes after the emergency stop is lifted.

6. The winder adopts the ergonomic design, and the operation position and roller height are fine-tuned for manual filament leading.

7. Each winder is well-sealed with positive inside pressure, which avoids carbon fiber filament going inside, a stable winding process can be guaranteed.

Videos of setting up and debugging can be offered?

winder installation and production, winder operation, remarks of debugging, daily maintenance, monthly maintenance, yearly maintenance, and so forth.

In warranty period: Due to equipment failure caused by the equipment itself, the seller should offer free repairment and related service; due to equipment failure caused by the buyer, the seller charges only the cost of spare parts.Out warranty period: The seller offers online technical support and service.