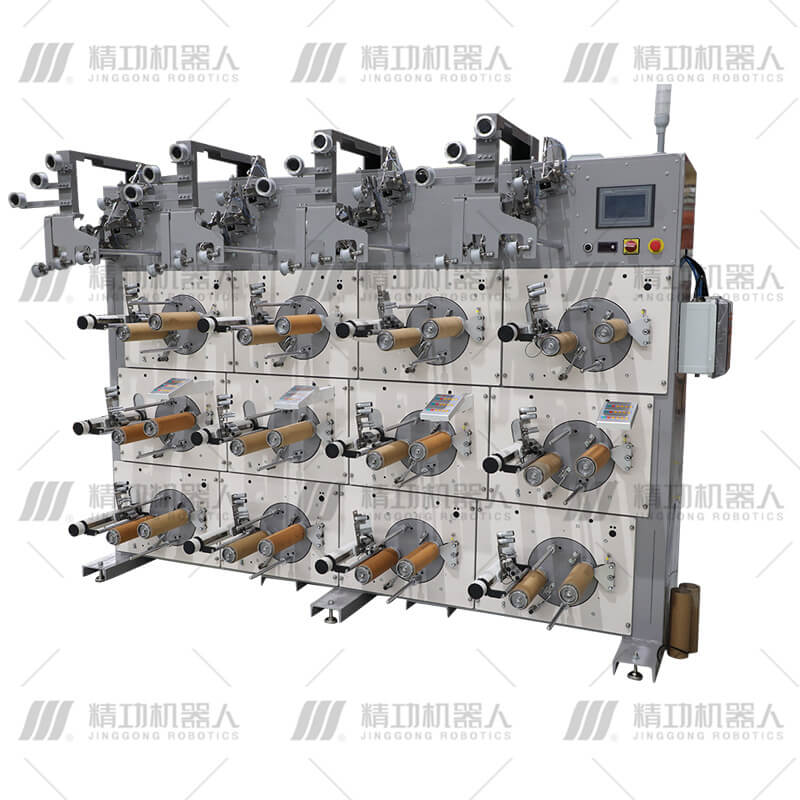

Carbon Fiber winder

Description

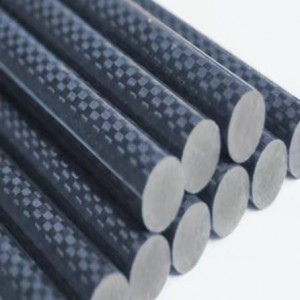

Carbon fiber is a new type of high strength and high modulus fiber material with carbon content above 90%, which has the characteristics of light weight, high strength, corrosion resistance, high modulus, low density, no creep, super high temperature resistance in non-oxidizing environment, good fatigue resistance, good electrical and thermal conductivity, etc. It not only has the inherent intrinsic characteristics of carbon materials, but also has the softness and processability of textile fibers, and is a new generation of reinforcing fiber.

Tech Specs

|

del specification / technical parameters |

Basic parameters of carbon wire winder with maximum winding capacity of 12kg

Basic parameters of carbon wire winder with maximum winding capacity of 20kg

|

Advantages

Main Key Technology:

Main Innovation:

Product Video

FAQ

Q: if a part of the equipment is damaged, can you provide the corresponding spare parts?

A: before the acceptance of the equipment, our company can provide corresponding spare parts for free; If within the warranty period, we can help customers to purchase, if necessary, we can purchase for you.

Q: can the equipment ensure that the carbon fiber is small and there is no risk of fiber invasion and damage when the production workshop is used for a long time?

A: each component of the equipment is designed and equipped with sealing function, which can ensure that the carbon fiber can not invade the control system in the cabinet, so as to protect the hardware system of the equipment.

Q: does the equipment have the expansion conditions for subsequent intelligent automatic wire cutting?

A: the equipment can provide the signal of pneumatic assisted wire lowering after the winding is full, and can interact with the follow-up expansion equipment.

User Evaluation

1. Low equipment failure rate, flexible operation, stable and reliable production;

2. The installation and adjustment of the equipment is very fast, and the after-sales remote response is very timely in case of doubt;

3. The key design is reasonable and easy to operate;

4. The random spare parts are complete and the random data of the equipment are accurate;

5. The winding process is good, and the end face forming effect is not inferior to the imported take-up machine!6. Winding diameter, gram weight and other winding parameters meet the expectations and industry standards.

Product Show

|

del specification / technical parameters |

Basic parameters of carbon wire winder with maximum winding capacity of 12kg

Basic parameters of carbon wire winder with maximum winding capacity of 20kg

|

main key technology :

1. The winding parameters are set accurately and reasonably to ensure that the end face of the product is beautiful and has no hair.

2. The reeling speed is accurate, and the winding tension is controlled reasonably. The whole winding is compact and full.

3. Take full account of the human-machine interaction, so that the operation is convenient and the wire drawing mode is reasonable.

4. The self reading of winding track is accurate and the spindle rotation speed is accurate and reasonable.

5. The accurate values of winding tension, winding ratio and other process parameters should be set according to the experience of different K number tow.

6. The protection level of the unit fully considers the particularity of carbon fiber conduction to ensure that the equipment itself is sealed in place and has heat exchange conditions.

main Innovation:

1. The new automatic cutting technology is adopted at the cutting position, with high cutting success rate, smooth fracture surface and stable winding action.

2. The new automatic tightening mechanism is adopted at the tightening part, with large tension force and no axial movement.

3. The new tension control mechanism is adopted at the lead wire, the swing arm angle feedback is accurate, and the tension control is stable.

4. The unit is designed and equipped with independent touch screen and PLC, and the human-computer interaction is smooth.

5. The new automatic wire pushing mechanism is adopted at the wire feeding position, which has a long pushing stroke, and can accurately give the wire pushing signal after pushing out, which can complete the automatic operation of the paper tube under the wire and on the paper pipe with the subsequent manipulator.

Q: if a part of the equipment is damaged, can you provide the corresponding spare parts?

A: before the acceptance of the equipment, our company can provide corresponding spare parts for free; If within the warranty period, we can help customers to purchase, if necessary, we can purchase for you.

Q: can the equipment ensure that the carbon fiber is small and there is no risk of fiber invasion and damage when the production workshop is used for a long time?

A: each component of the equipment is designed and equipped with sealing function, which can ensure that the carbon fiber can not invade the control system in the cabinet, so as to protect the hardware system of the equipment.

Q: does the equipment have the expansion conditions for subsequent intelligent automatic wire cutting?

A: the equipment can provide the signal of pneumatic assisted wire lowering after the winding is full, and can interact with the follow-up expansion equipment.

1. Low equipment failure rate, flexible operation, stable and reliable production;

2. The installation and adjustment of the equipment is very fast, and the after-sales remote response is very timely in case of doubt;

3. The key design is reasonable and easy to operate;

4. The random spare parts are complete and the random data of the equipment are accurate;

5. The winding process is good, and the end face forming effect is not inferior to the imported take-up machine!6. Winding diameter, gram weight and other winding parameters meet the expectations and industry standards.