Carbon Fiber Production Line

Parmeters

| Item | Parameter | Remark |

| Raw material | PAN-based precursor | |

| Suitable tow specifiation | 12K、24K、48K、96K | |

| Denier per filament d/tex | 1.22 | |

| Oven width(mm) | 500-3000 | |

| Running speed(m/min) | 6-12 | |

| Oxidation temperature(℃) | 300 | |

| LT temperature(℃) | 1000 | |

| HT temperature(℃) | 1800 | |

| Production capacity (Ton/Year) | about1500(12K,400tow,12 m/min,7200hrs) |

Description

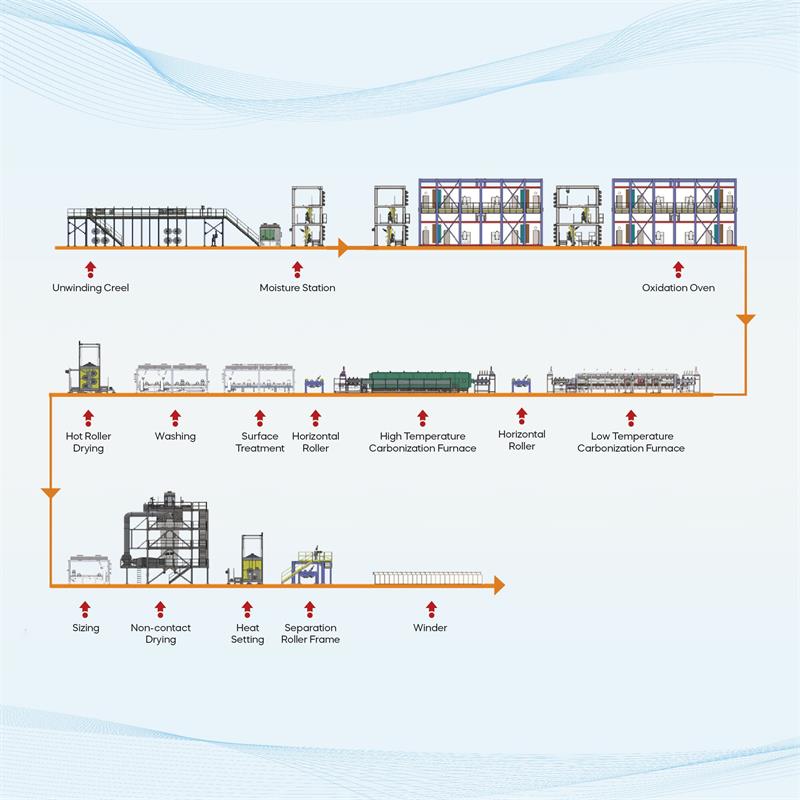

1、Equipment Brief

Jinggong Science&Technology has introduced the advanced international technology for this carbon fiber production line and mutually developed it with a partner who has decades of experience in carbon fiber processing. The line consists of creel, oxidation ovens, low temperature furnace, high temperature furnace, surface treatment equipment, sizing equipment, hot dryer and winder, etc. it can realize and get continuous heat treatment and post-processing treatment for PAN-based precursor. The line adopts integrated control system by synthesizing PC technology, internet communication technology, redundancy and self-detecting technology, it is a fully automatic continuous carbon fiber production line.

①creel

② Oxidation oven

③LT furnace

④ Horizontal roller

⑤HT furnce

⑥ Surface treatment

⑦ Sizing and vertical dryer

⑧ winder

Product Video

Product Show

| Item | Parameter | Remark |

| Raw material | PAN-based precursor | |

| Suitable tow specifiation | 12K、24K、48K、96K | |

| Denier per filament d/tex | 1.22 | |

| Oven width(mm) | 500-3000 | |

| Running speed(m/min) | 6-12 | |

| Oxidation temperature(℃) | 300 | |

| LT temperature(℃) | 1000 | |

| HT temperature(℃) | 1800 | |

| Production capacity (Ton/Year) | about1500(12K,400tow,12 m/min,7200hrs) |

Jinggong robot has introduced the advanced international technology for this carbon fiber production line and mutually developed it with a partner who has decades of experience in carbon fiber processing. The line consists of creel, oxidation ovens, low temperature furnace, high temperature furnace, surface treatment equipment, sizing equipment, hot dryer and winder, etc. it can realize and get continuous heat treatment and post-processing treatment for PAN-based precursor. The line adopts integrated control system by synthesizing PC technology, internet communication technology, redundancy and self-detecting technology, it is a fully automatic continuous carbon fiber production line.