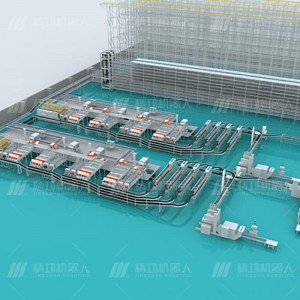

Laser Welding Equipment for Water Pump Impeller

Description

For laser welding of water pump blade

● High precision six-axis industrial robots

● Laser+laser welding head system

● laser welding head

● Duplex/Triplex mechanical rotary table

● Robot transfer module

● Multi-station turntable module

● Electrical control system

Tech Specs

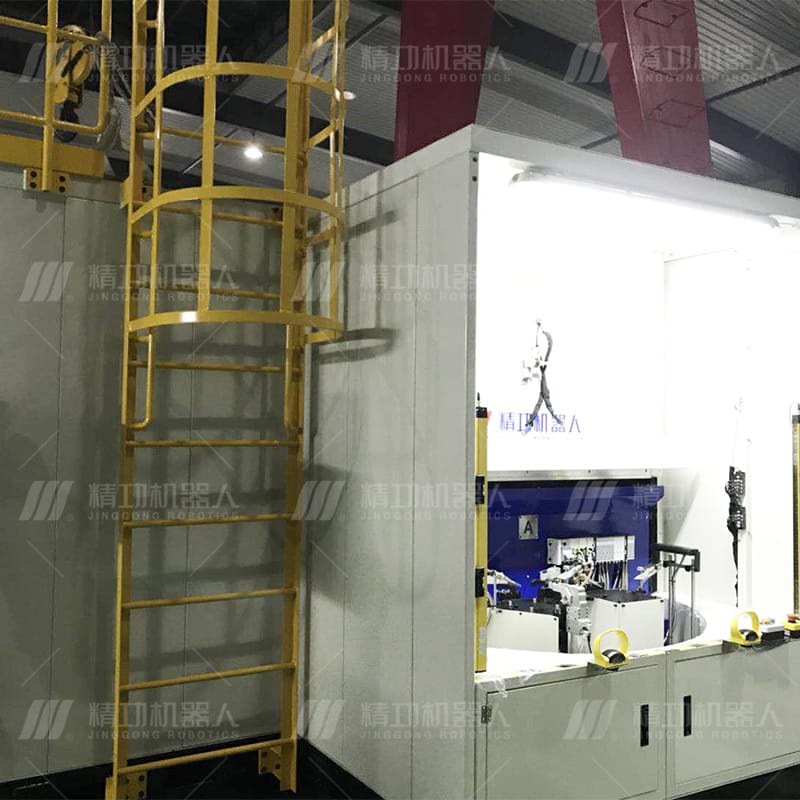

It consists of robot system, laser + laser welding joint system, automatic laser welding fixture, smoke and dust treatment system, double position turntable system, integrated welding room protection system and a set of electrical control system. In addition to manual loading and unloading, the rest of the actions are automatically completed.

Advantages

Change the traditional argon arc welding production method, welding speed, high precision, small post-welding deformation, beautiful appearance, the weld does not require subsequent processing (such as turning, grinding, etc.)

Product Video

FAQ

Q: if a part of the equipment is damaged, can you provide the corresponding spare parts?

A: before the acceptance of the equipment, our company can provide corresponding spare parts for free; If within the warranty period, we can help customers to purchase, if necessary, we can purchase for you

User Evaluation

In batch production, the welding quality is stable

Product Show

It consists of robot system, laser + laser welding joint system, automatic laser welding fixture, smoke and dust treatment system, double position turntable system, integrated welding room protection system and a set of electrical control system. In addition to manual loading and unloading, the rest of the actions are automatically completed.

Change the traditional argon arc welding production method, welding speed, high precision, small post-welding deformation, beautiful appearance, the weld does not require subsequent processing (such as turning, grinding, etc.)

Q: if a part of the equipment is damaged, can you provide the corresponding spare parts?

A: before the acceptance of the equipment, our company can provide corresponding spare parts for free; If within the warranty period, we can help customers to purchase, if necessary, we can purchase for you

In batch production, the welding quality is stable