OEM Pes Handheld Laser Welder Manufacturers – Melt-Blown Spinning Machine Melt Blown Water Polting Production Line – Jinggong

OEM Pes Handheld Laser Welder Manufacturers – Melt-Blown Spinning Machine Melt Blown Water Polting Production Line – Jinggong Detail:

Melt-Blown Spinning Machine Melt Blown Water Polting Production Line

Description

The production line consists of unwinding system, pure water preparation system, Spunlaced electret system (water ring vacuum pump unit), drying and locking system, slitting and winding system and other components. The prepared pure water is delivered to the fan-shaped nozzle by high-pressure pump. The fan-shaped nozzle spurs the melt blown non-woven fabric on one side. The electric charge is generated by the friction between the pure water and the melt blown cloth to complete the spunlaced electrostatic electret.

Tech Specs

● Model: jgrmwel-1600;

● Equipment size: 18m (L) x 8m (W) x 3.5m (H);

● Rated power: About 500kW;

● Resistivity of ultrapure water: 15-18.2m Ω cm

● Output: 1.5-2 tons per day (according to the quality grade of melt blown fabric);

● Width of electret of finished fabric: 1600mm;

● Filtration grade of finished cloth: when the air volume is 95L / min, the test filtration rate of paraffin oil should reach the oily P2 (96 ~ 97% above).

Advantages

Compared with the traditional production line of corona electret melt blown fabric, the spunlaced electret production line developed by our company after spunlacing, the fabric performance is saturated with static electricity, and the static electret retention time is longer; It can effectively solve the difficulties of improving the electret efficiency and reducing the efficiency after storage in the mask industry; The equipment has a high degree of automation and low requirements for operators; The filtration efficiency of spunlaced electret can reach more than 95% or even more than 99%. Static electricity does not decay (up to more than 2 years), and low resistance (about 3 ~ 40%) is low resistance and high efficiency; Equipment installation, operation training and maintenance are supplemented with detailed documents and materials to relieve customers of difficulties in daily operation and maintenance.

Product Video

FAQ

User Evaluation

Stable and reliable operation of production line, produced by large factories!The after-sales response was very fast. I was most worried that the machine would stop. The engineer immediately solved the problem remotely.

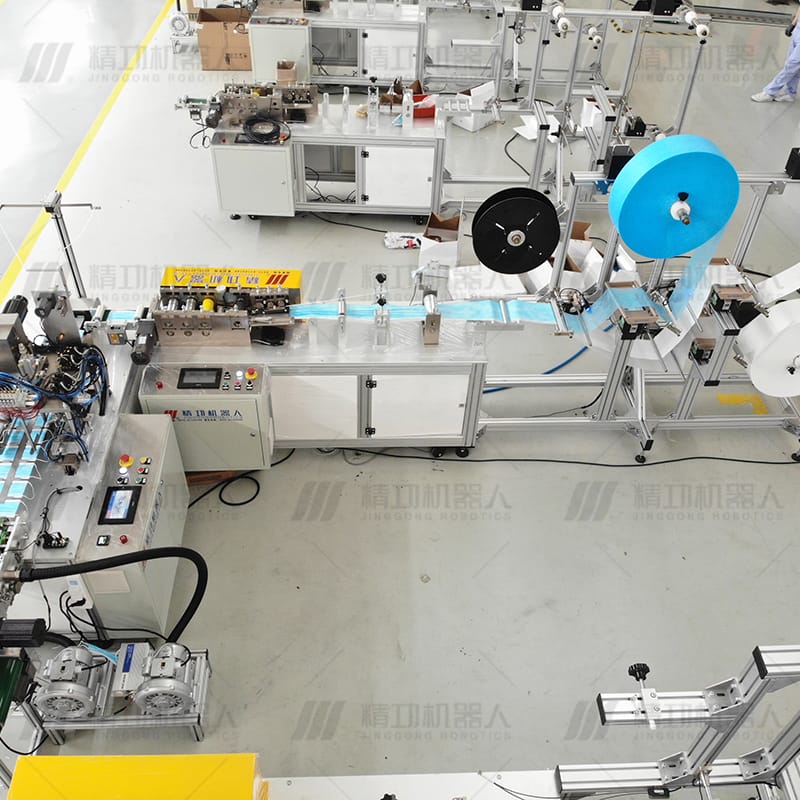

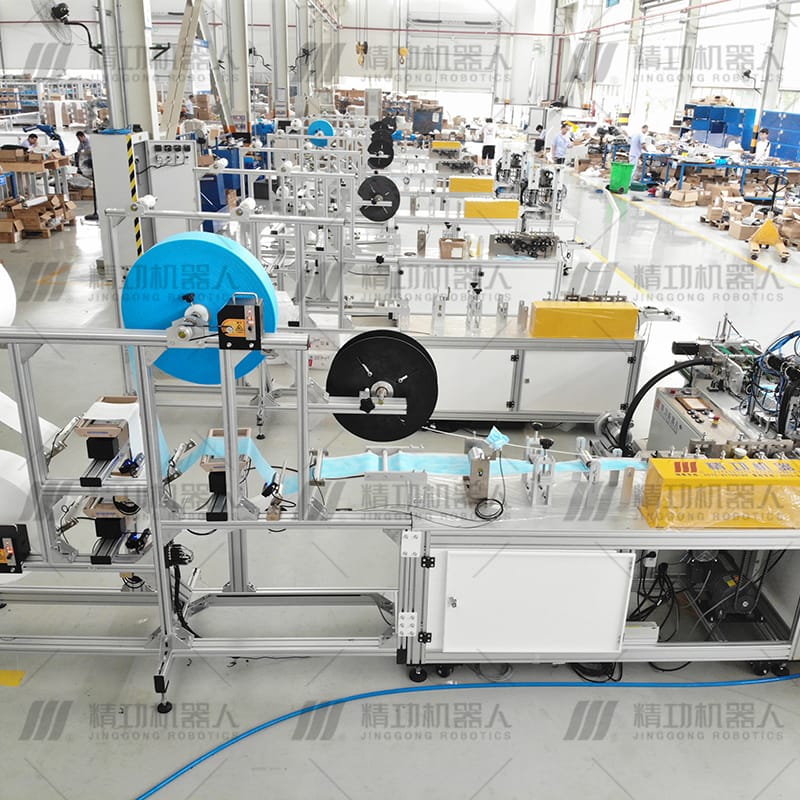

Product Show

Product detail pictures:

Related Product Guide:

As for aggressive rates, we believe that you will be searching far and wide for anything that can beat us. We can easily state with absolute certainty that for such good quality at such charges we are the lowest around for OEM Pes Handheld Laser Welder Manufacturers – Melt-Blown Spinning Machine Melt Blown Water Polting Production Line – Jinggong , The product will supply to all over the world, such as: Bolivia, Rio de Janeiro, Yemen, With the intensified strength and more reliable credit, we are here to serve our customers by providing the highest quality and service, and we sincerely appreciate your support. We will endeavor to maintain our great reputation as the best products supplier in the world. If you have any questions or comments, please contact with us freely.

The company's products can meet our diverse needs, and the price is cheap, the most important is that the quality is also very nice.