OEM Agv Robots Hospitals Factory – Logistics Distribution Management – Jinggong

OEM Agv Robots Hospitals Factory – Logistics Distribution Management – Jinggong Detail:

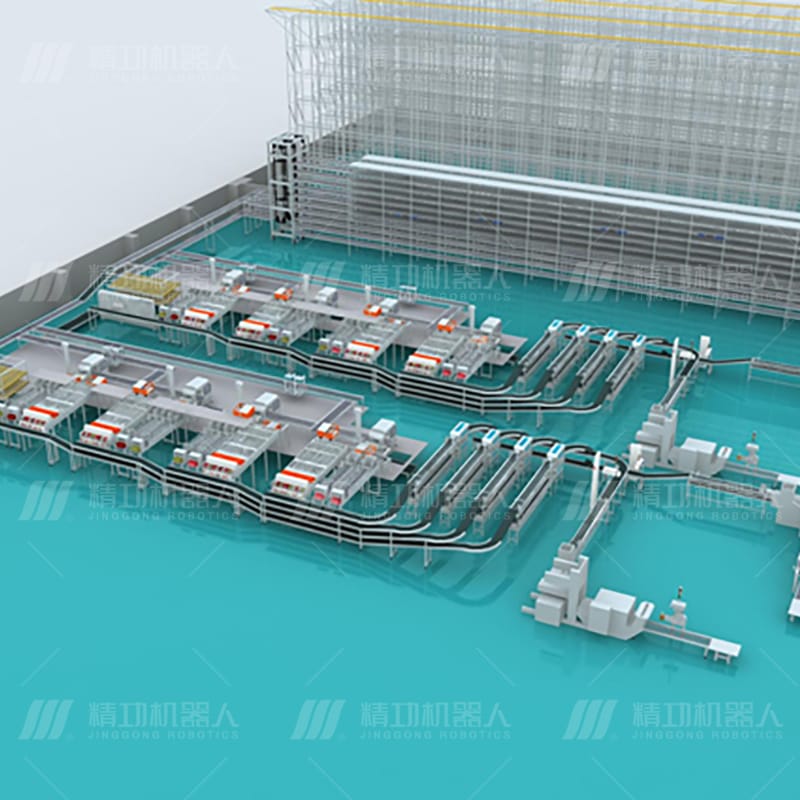

The logistics distribution management system provides a complete information management solution for the complex and changeable automatic production line material processing system and automatic distribution system at present and in the future. It has the advantages of simple and intuitive system operation, support for multi language, parametric configuration, dynamic plug-in expansion and so on. It provides the optimal picking strategy for the order processing of the distribution center, and can optimize and improve the picking efficiency of the distribution center.

The project development life cycle management is standardized through CMMI3 to ensure the stability and high reliability index of the system and meet the long-term uninterrupted operation of the system. At present, the logistics distribution management system includes tars (automatic replenishment system), TASS (automatic sorting system) and tinf module.

main functional modules

(1) Automatic replenishment system (tars)

The automatic replenishment system is a system between the warehouse management system and the sorting system. It can dynamically adjust the replenishment plan of sorting materials by obtaining the available inventory and operation status of the warehouse management system, the system inventory and sorting capacity of the sorting system in real time, so as to realize continuous replenishment to the sorting system and ensure the smooth operation of the sorting system. By monitoring the status of warehouse and sorting equipment in real time and the implementation status of conveying material tasks, the conveying strategy can be changed in time as needed.

(2) Automated sorting system (TASS)

The automatic sorting system is to meet the sorting needs of various materials in the distribution center by integrating diversified equipment, provide the optimal transportation or sorting path, and control the beat of internal operation units in the distribution center in real time, so as to make the whole sorting process reasonable and orderly. And integrate the diversified storage, transportation, picking, identification, information prompt and other equipment of the distribution center.

Through the control of the control device, classification device, conveying device and classification crossing, the continuous and large-scale material distribution can be realized, the automatic picking can be carried out according to the order, line, area and wave order, the production requirements with extremely low error rate can be met, and the real-time picking status can be fed back to the control personnel through the monitoring system.

Make full use of Internet of things technology, intelligently control the business processes of the distribution center, and generate reasonable dispatching instructions (preprocessing technology) in advance to effectively improve operation efficiency.

(3) Integrated interface module (tinf)

Through the interface middleware tinf, the integration with the upper information system is realized, and the enterprise information integration platform is built.

system advantages

(1) Flexible order optimization strategy

The system designs a configurable order optimization strategy, which can be flexibly adjusted according to the demand (such as average distribution strategy, material limit strategy, out of tolerance strategy, etc.), and can process orders in batch and real-time dynamically, which can effectively improve the order picking efficiency.

(2) pretreatment strategy

The system has intelligent data preprocessing strategy, which can preprocess the execution data of order tasks in combination with the actual operation of the system, and effectively improve the operation efficiency of the system.

(3) Flexibility

Centralized management and decentralized control are adopted, so that the system has high flexibility and data processing can be distributed flexibly.

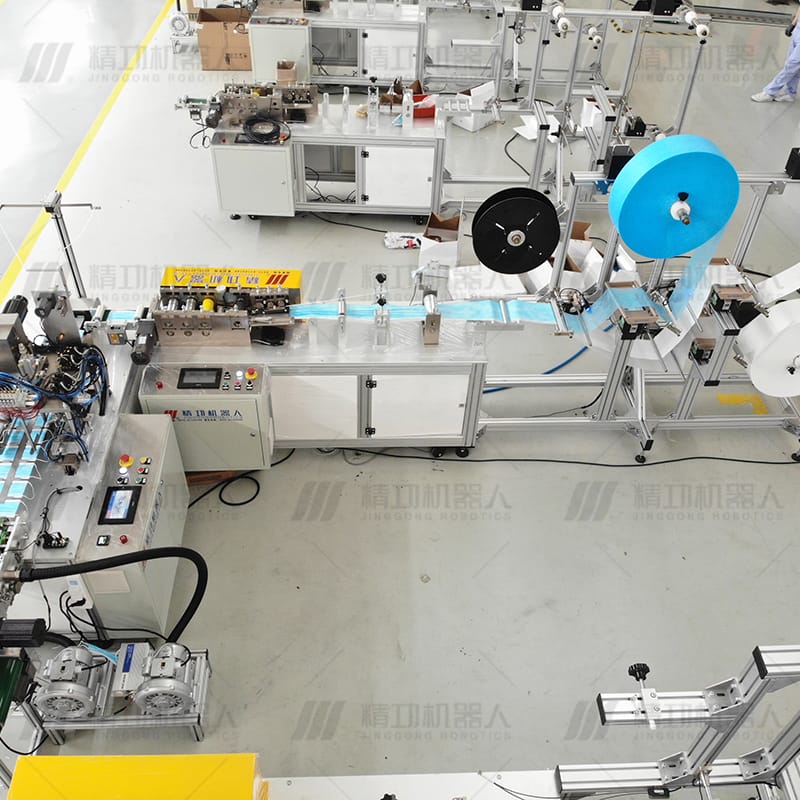

Product detail pictures:

Related Product Guide:

We are convinced that with joint efforts, the business between us will bring us mutual benefits. We can assure you product quality and competitive price for OEM Agv Robots Hospitals Factory – Logistics Distribution Management – Jinggong , The product will supply to all over the world, such as: Honduras, Sacramento, Miami, Our company follows laws and international practice. We promise to be responsible for friends, customers and all partners. We would like to establish a long-term relationship and friendship with every customer from all over the world on the basis of mutual benefits. We warmly welcome all old and new customers to visit our company to negotiate business.

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!