ODM Automated Forklift Robot Factory – Automatic Packaging Line For DTY – Jinggong

ODM Automated Forklift Robot Factory – Automatic Packaging Line For DTY – Jinggong Detail:

Description

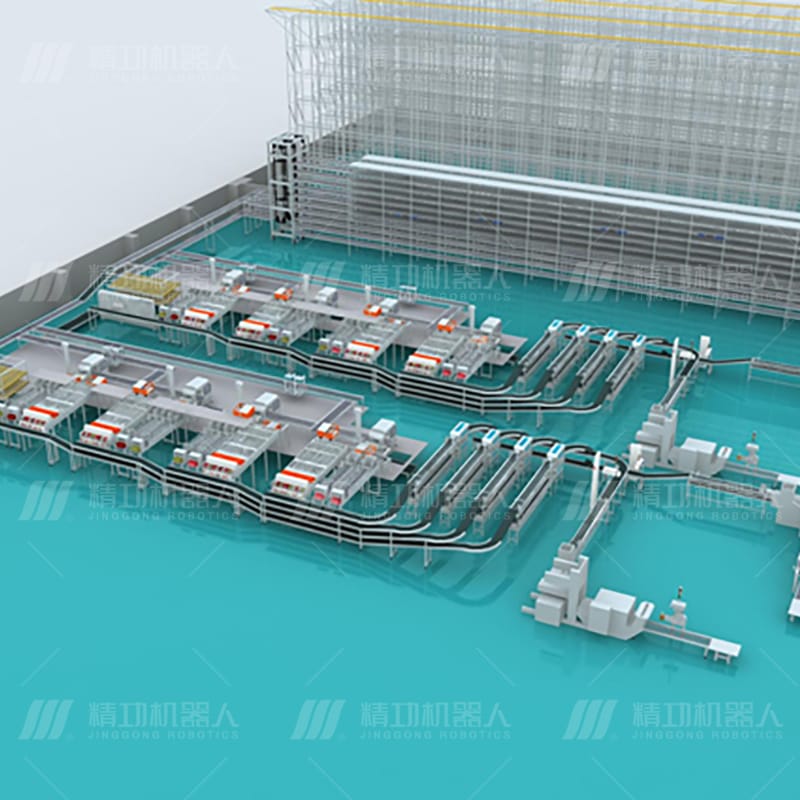

The DTY packaging line is used to enhance your factory effiency and reduce your labor intensity. The packing process are as follows:

1. To put the DTY yarn from the yarn trolley to cartons, the carton should be put and opened on the packaging line, and filled with the DTY yarn manually.

2. In filling, the weighting mechanism under the conveyor will send the weight to the computer. After being checked manually, a label, being printed by the label pringting device, needs to be sticked on the carton manually. Then the carton is conveyed forward.

3. The carton sealing machine will close the carton and seal it.

4. After sealing, the carton will be taped in landscape orientation.

5. After taping, the carton will be sent forward to the section of carton catching.

6. As programmed, the robot will catch the carton and put it on the pallet, and fulfilling the task of automatic stacking.

The control system adopts PLC. The data collected by sensors will be sent to the CPU through the Internet, through which the processed data will be output to the actuators.

The system adopts two types of operation mode: manul and automatic.

And the line is highly customiazble.

video

Tech Specs

The components of the packaging line are as follows:

|

NO. |

NAME |

DESCRIPTION |

UNIT(SET) |

BRAND |

|

1 |

Stacking Robot

|

JGR120,4-axis,Rated Load 120kg,Pneumatic Manipulator |

1 |

JINGGONG

|

|

2 |

Automatic Carton Sealer

|

Automatic Carton Closing and Sealing |

1 |

JINGGONG

|

|

3 |

Automatic Carton Taping Machine |

1 |

JINGGONG

|

|

|

4 |

Conveyor |

Roller Conveyor |

1 |

JINGGONG |

|

5 |

Weighting Device |

Online Weighting Platform |

1 |

JINGGONG |

|

6 |

Computer and Printer |

With One Computer and One Printer(Working Table Excluded) |

1 |

LOCAL |

|

7 |

Electronic Control System |

PLC |

1 |

JINGGONG |

|

8 |

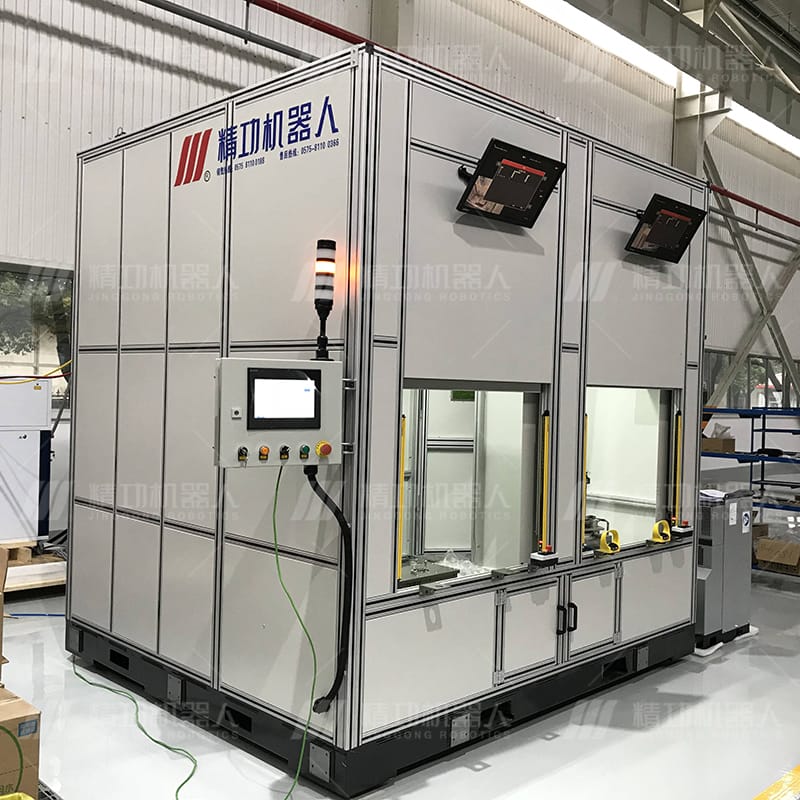

Stockade |

With Security Lock |

1 |

JINGGONG |

|

9 |

Others |

Other Accessories and Spare Parts |

1 |

JINGGONG

|

Specs of Each Device

Automatic Carton Sealer

| Power Supply | AC380V 50Hz 0.4kW |

| Air Pressure Requirement | 0.4 MPa-0.6 MPa |

| Sealing Means | Kraft paper tape, BOPP tape |

| Tape Width | 48mm~72mm |

| Carton Size | 200mm~550mm(L); 150mm~480mm(W); 120mm~480mm(H)(Customizable) |

| Sealing Speed | 20m/min |

| Device Height | 550mm~750mm(Machine Feet), 650mm~800mm(Machine Caster). The height is adjustable. |

| Machine Size | 1650mm(L) × 890mm(W) × 890mm+Woking Table Height(H) |

Automatic Carton Taping Machine

| Power Supply | 380V 50/60Hz 1.0kW |

| Machine Size | 1905mm(L) × 628mm(L) × 1750mm(H) |

| Taping Size | Min. Carton Size:80mm(L) × 60mm(H) |

| Standard Frame Size | 800mm(W) × 600mm(H) (Customizable) |

| Woking Table Height | 450mm(Customizable) |

| Max. Payload | 80 kg |

| Taping Speed | ≤2.5Second/Tape |

| Force | 0~60kg(Adjustable) |

| Tape Size | 9-15(±1)mm(w), 0.55-1.0(±0.1)mm(Thickness) |

| 9-15(±1)mm(w), 0.55-1.0(±0.1)mm(Thickness) | 160-180mm(W), 200-210mm(ID), 400-500mm(OD) |

| Taping Means | Parallel Taping with inching switch, continuous switch, ball switch, foot switch, or so forth. |

| Binding Means | Heat Fusion, Bottom Fusion, Fusion Plane≥90%,Fusion Tolerance≤2mm |

| Machine Weight | 270kg |

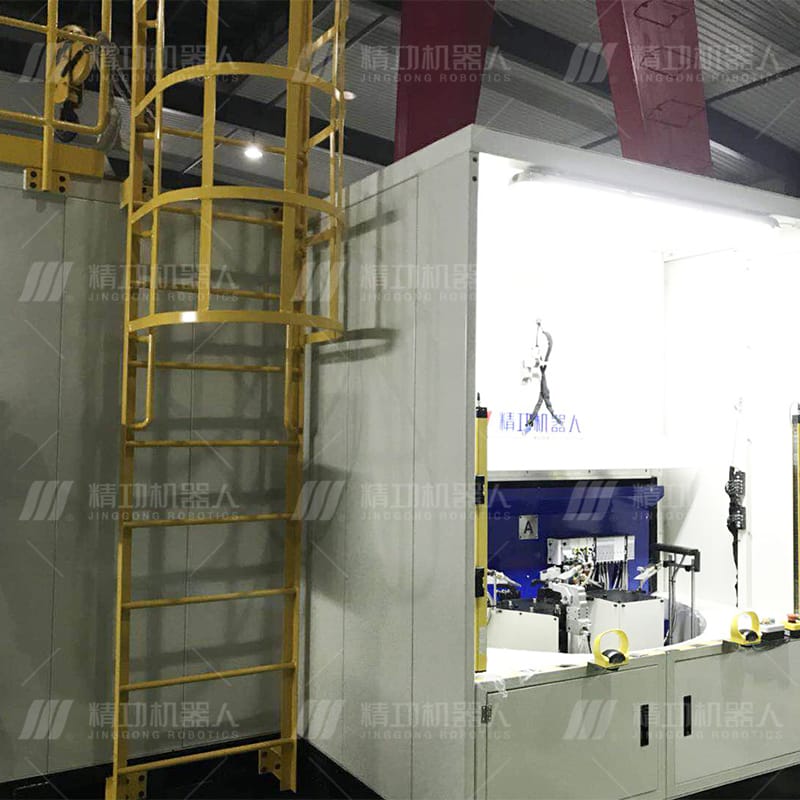

Stacking Robot

|

JGR120 |

|

|

Mechanical Structure |

Vertical Multi-Joint Type |

|

Number of Axis |

4 |

|

Positioning Accuracy in Repetition |

±0.2mm |

|

Max. Payload |

120kg |

|

Power Supply Capacity |

30KVA |

|

Weight |

1350KG |

|

Working Range |

2600mm |

|

Power Supply Capacity |

30KVA |

|

Electric Cabinet Size |

1000*700*1200 |

|

Electric Cabinet Weight |

180KG |

|

Power Supply |

380V, 3-phrase 5-wire |

|

Installation Means |

On the Ground |

|

Screen Size |

7.8 inch Color Touch Screen |

|

Protection Level |

IP54 |

The above specifications are for your reference only, please subject to the actual machine.

Advantages

The control system adopts PLC. The data collected by sensors will be sent to the CPU through the Internet, through which the processed data will be output to the actuators.

The system adopts two types of operation mode: manul and automatic.

And the line is highly customiazble.

Product detail pictures:

Related Product Guide:

Gaining purchaser gratification is our company's aim eternally. We're going to make great initiatives to create new and top-quality products, satisfy your exclusive prerequisites and supply you with pre-sale, on-sale and after-sale solutions for ODM Automated Forklift Robot Factory – Automatic Packaging Line For DTY – Jinggong , The product will supply to all over the world, such as: Russia, Provence, US, Item have passed by means of the national qualified certification and been well received in our main industry. Our expert engineering team will often be ready to serve you for consultation and feedback. We have been able to also deliver you with cost-free samples to meet your specs. Ideal efforts will probably be produced to deliver you the most beneficial service and solutions. Should really you be interested in our company and solutions, please make contact with us by sending us emails or call us straight away. To be able to know our solutions and enterprise. ar more, you'll be able to come to our factory to see it. We will constantly welcome guests from all over the world to our firm. o build business enterprise. elations with us. You should feel absolutely free to speak to us for organization. nd we believe we are going to share the best trading practical experience with all our merchants.

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.