High-Quality Agv Machines Factory – Melt-Blown Spinning Machine Melt Blown Water Polting Production Line – Jinggong

High-Quality Agv Machines Factory – Melt-Blown Spinning Machine Melt Blown Water Polting Production Line – Jinggong Detail:

Video

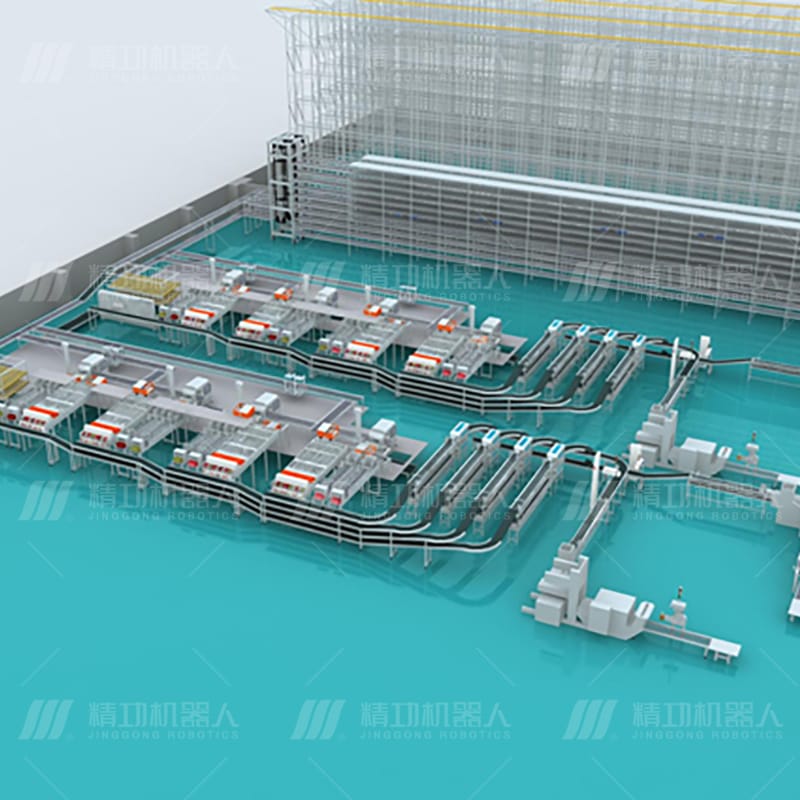

Melt-Blown Spinning Machine Melt Blown Water Polting Production Line

Description

The production line consists of unwinding system, pure water preparation system, Spunlaced electret system (water ring vacuum pump unit), drying and locking system, slitting and winding system and other components. The prepared pure water is delivered to the fan-shaped nozzle by high-pressure pump. The fan-shaped nozzle spurs the melt blown non-woven fabric on one side. The electric charge is generated by the friction between the pure water and the melt blown cloth to complete the spunlaced electrostatic electret.

Tech Specs

● Model: jgrmwel-1600;

● Equipment size: 18m (L) x 8m (W) x 3.5m (H);

● Rated power: About 500kW;

● Resistivity of ultrapure water: 15-18.2m Ω cm

● Output: 1.5-2 tons per day (according to the quality grade of melt blown fabric);

● Width of electret of finished fabric: 1600mm;

● Filtration grade of finished cloth: when the air volume is 95L / min, the test filtration rate of paraffin oil should reach the oily P2 (96 ~ 97% above).

Advantages

Compared with the traditional production line of corona electret melt blown fabric, the spunlaced electret production line developed by our company after spunlacing, the fabric performance is saturated with static electricity, and the static electret retention time is longer; It can effectively solve the difficulties of improving the electret efficiency and reducing the efficiency after storage in the mask industry; The equipment has a high degree of automation and low requirements for operators; The filtration efficiency of spunlaced electret can reach more than 95% or even more than 99%. Static electricity does not decay (up to more than 2 years), and low resistance (about 3 ~ 40%) is low resistance and high efficiency; Equipment installation, operation training and maintenance are supplemented with detailed documents and materials to relieve customers of difficulties in daily operation and maintenance.

Product Video

FAQ

User Evaluation

Stable and reliable operation of production line, produced by large factories!The after-sales response was very fast. I was most worried that the machine would stop. The engineer immediately solved the problem remotely.

Product Show

Product detail pictures:

Related Product Guide:

With responsible good quality method, good status and excellent client services, the series of solutions produced by our company are exported to lots of countries and regions for High-Quality Agv Machines Factory – Melt-Blown Spinning Machine Melt Blown Water Polting Production Line – Jinggong , The product will supply to all over the world, such as: Bhutan, Sacramento, India, Our staffs are rich in experience and trained strictly, with qualified knowledge, with energy and always respect their customers as the No. 1, and promise to do their best to deliver the effective and individual service for customers. The Company pays attention to maintaining and developing the long-term cooperation relationship with the customers. We promise, as your ideal partner, we'll develop a bright future and enjoy the satisfying fruit together with you, with persisting zeal, endless energy and forward spirit.

The company can keep up with the changes in this industry market, product updates fast and the price is cheap, this is our second cooperation, it's good.