Laser Welding Equipment For Car Heat Exchanger

Description

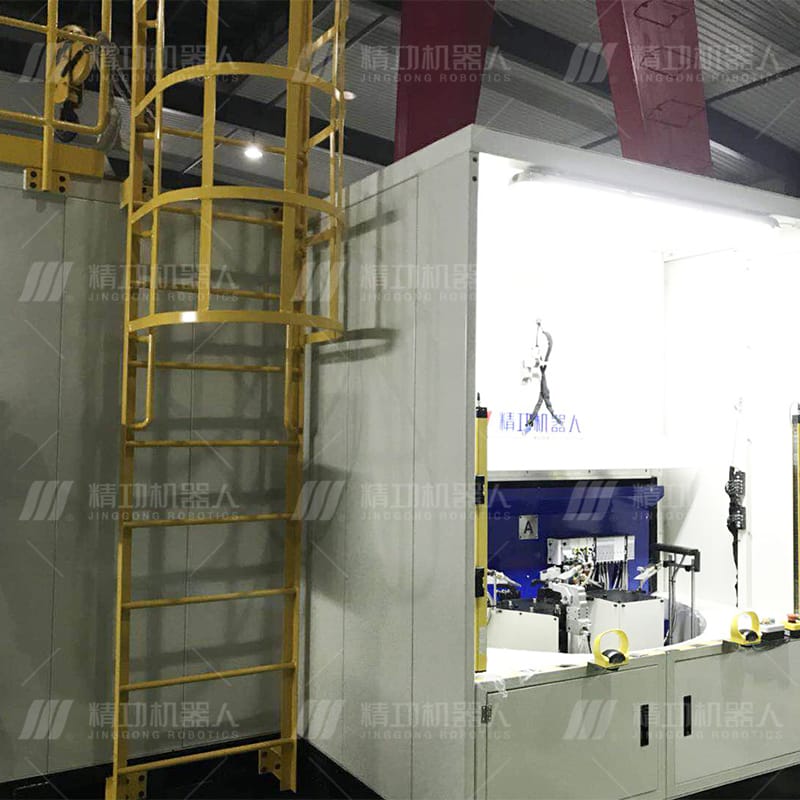

A plate heat exchanger workstation for automatic laser welding

● Robotic Systems

● Laser Systems

● Turntable system

● Variable position machine system

● Automatic welding fixture

● Dust removal system

● PLC electronic control system

Tech Specs

The workstation includes Robot system, laser system, turntable system, positioner system, automatic welding Fixture, dust removal system and one set PLC Electronic control system, One person operation completes loading and unloading, and the rest is completed automatically

Advantages

The use of laser welding can effectively reduce the amount of deformation of the heat sink plate, reduce the degree of damage, higher welding accuracy, improve the welding quality of the product, ensure that the heat transfer efficiency of the product is not affected by the welding, improve the performance of the product, and the welding efficiency has also been improved.

Product Video

FAQ

Q: equipment training?

A: when the equipment is sent out, there will be programming, debugging, product change, working principle introduction and other information to customers (for engineers, technicians and operators)

User Evaluation

batch In production, welding quality Meet requirements

Product Show

The workstation includes Robot system, laser system, turntable system, positioner system, automatic welding Fixture, dust removal system and one set PLC Electronic control system, One person operation completes loading and unloading, and the rest is completed automatically

The use of laser welding can effectively reduce the amount of deformation of the heat sink plate, reduce the degree of damage, higher welding accuracy, improve the welding quality of the product, ensure that the heat transfer efficiency of the product is not affected by the welding, improve the performance of the product, and the welding efficiency has also been improved.

Q: equipment training?

A: when the equipment is sent out, there will be programming, debugging, product change, working principle introduction and other information to customers (for engineers, technicians and operators)

batch In production, welding quality Meet requirements